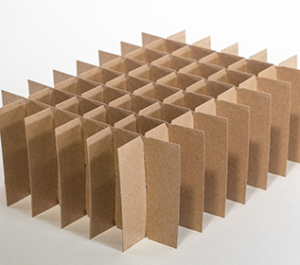

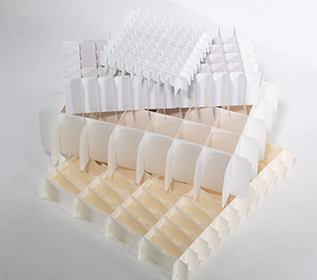

Chipboard partitions are available in a wide range of board thicknesses, called calibers. These calibers range from .018″ to .060″ in single ply and from .070″ to .200″ in pasted or multi-ply forms. Box partition strength and flexibility depends heavily on the chipboard’s caliber. Thin calibers create standard protection, while mid-grade calibers offer greater rigidity and stacking strength. Thicker caliber chipboard materials (i.e. Pasted / multi-ply) are extremely strong, used primarily for heavy products. All calibers are in stock at all times.

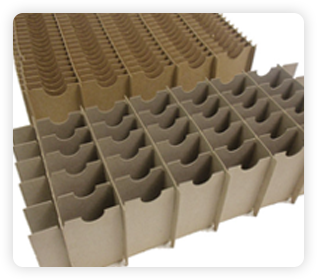

Regular chipboard partition material can be used for many products that do not require special coatings. However, chipboard partition material is also available with a smooth finish and poly coat. These finishes provide additional protection to more fragile products which may be susceptible to scratching and scuffing. Both finishes also have significantly less lint allowing customers to pack and deliver a much cleaner product. Solid black board is also offered and used typically for fine chocolates and other delicacies. All finishes are in stock at all times.

Chipboard partitions offer a variety of optional features including “V” notches, locking dies, “S” notches, and half moon notches. The use of these features enhances the “performance” of the box partition. Orientation and corner cuts can be created to ease the insertion of the box partition into cartons. Locking mechanisms are used to firmly hold a partition together prior to insertion into the carton. Half moons allow the customer to grasp the product and remove it from the packaging quickly and efficiently. Finally, stamping / printing of customer logos, recyclable symbols or other message content can be placed on chipboard partitions.

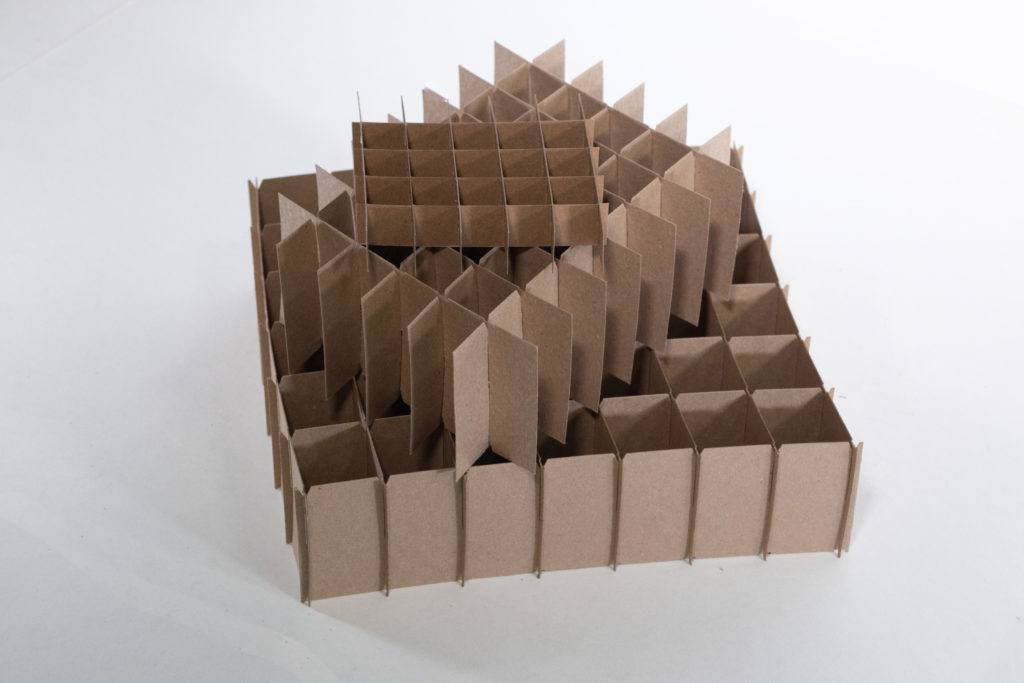

Chipboard partitions work very well with awkward product shapes and sizes. Chipboard partitions can be designed for any standard or custom carton size. Air cells (empty cells around the outside perimeter of the partition matrix) function as an extra level of support/protection for delicate products. Chipboard partitions lengths and widths range from 1 to 50 inches, and heights from 13/16 to 16 inches. Cell sizes can be as small as 3/8″ x 3/8″. General Partition design engineers are always on hand to help create new packs, revise old ones, and to answer any and all questions.